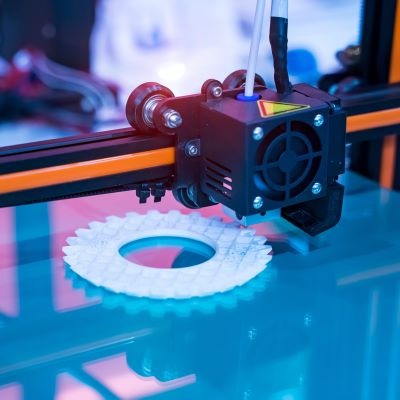

UF engineers have developed a new 3D printing method called vapor-induced phase-separation 3D printing, or VIPS-3DP, that uses more sustainable materials and less energy than current methods, says researcher Yong Huang.

When printing with its special eco-friendly liquids, which may include metal or ceramic particles, a non-solvent vapor is released into the printing area. This vapor makes the liquid part of the ink solidify, leaving behind solid material. The process will allow manufacturers to print parts that include different kinds of substances at different locations and varied levels of porousness. This could be useful for manufacturing objects such as porous medical implants or lightweight aerospace products.

View Related Expert Profiles: Go to Source